The Industrial Internet of Things (IIoT) refers to interconnected sensors, instruments, and other devices networked together

Optimal IIOT

(IIoT) refers to interconnected sensors, instruments, and other devices networked together with computers' industrial applications, including manufacturing and energy management.

This connectivity allows for data collection, exchange, and analysis, potentially facilitating improvements in productivity and efficiency as well as other economic benefits.[1] The IIOT is an evolution of a distributed control system (DCS) that allows for a higher degree of automation by using cloud computing to refine and optimize the process controls. – Wikipedia.

Optima’s IIOT devices and technology bring a high level of intelligence and unique applied sensors and video to keep your planting operating as efficiently and profitable as possible.

The Inner Eye (NRI)

The NRI mill loading sensor provides critical mill loading information to ensure that your mill is constantly operating at peak performance on a moment by moment basis. The NRI Mill charge sensor is an Industrial Internet of Things (IIOT) hub for gathering and processing large quantities of real time process data related to SAG and ball mill operations. Technically speaking, dozens of sensors of all different types can be located on the mill to take any number of measurements such as liner wear, ball charge, mill loading, realtime ore hardness etc. This information can then be transmitted to various users such as the DCS, maintenance platforms, etc. Robust signals along the radial axis for charge intensity and strike zone are generated and broadcast such that the mill can be operated as efficiently as possible; ensuring efficient work is happening in the mill. This information can be used by operators in an open loop fashion or incorporated into closed loop multivariable control strategy.

NRI Shell Mounted Sensor

The shell-mounted, power-harvesting design is such that there can be essentially any amout of power available to the mill shell for powering numerous sensors. The lack of meaningful amounts of constant power to the mill shell has historically been a big hurdle for making robust measurements on operational mills. The NRI overcomes this limitation.

The new sensor system mounted on the mill shell delivers falling charge intensity and strike zone information with regards to the process inside the mill and doesn’t require batteries. The sensor comes in two form factors – natural magnets or electromagnets. Pictured here is the natural magnet configuration.

The NRI Comprises Five Basic Systems or Parts

1. Vibration Sensors

Multiple vibration or final element sensors can be positioned at various locations on the mill. Optima will provide 3 vibration sensors to measure the feed, discharge and middle section of each section of the mill.

2. Computer & Power Conditioner

An onboard computer provides computational power for signal processing.

3. Power Harvester

The computer is powered by a patented induction power generator. Coils are mounted on the rotating shell wall comprising the rotor. These coils are coupled with a bank of natural or electromagnets, comprising the stator, that are mounted on a bracket attached to any adjacent beam or structure.

4. Wireless Transmission & Reception

The measurements are passed from the mill via a wireless transmission to the receiver/transmitter located on the control room floor within 20 feet of each rotor. The signals are then transferred to the computer running an AutoPilot® controller for signal processing.

5. Final Signal Preparation (Software/Computer)

Once the signal is received at the AutoPilot® computer, the measurements are processed and sent to an NRI web based browser, or to the DCS, or to both depending on plant preferences.

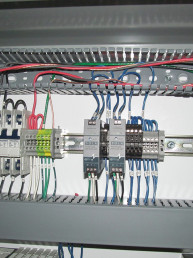

Continuous Flow Reagent Pumping Station

Ensure that your process gets just the right amount of reagent to maximize recovery while minimizing costs 24 hours a day 365 days a year

Flotation, CIL, and many other types of circuits operate best with an uninterrupted supply of reagents and precisely dosed chemical additives. Optima engineers and manufactures custom small to medium size continuous reagent dosing system for closed loop ratio control of your critical and costly reagents. Tighter control means less waste and better results.

Optima systems can handle the pumping and precise measuring of reagents. These systems are stout and mobile, designed to withstand the punishing mining environment. Systems can be configured with their own controls system or integrated into your existing system. Optima pumping systems are fully redundant to keep you processing without a hiccup.